ABB is a technology leader that is driving the digital transformation of industries. The Porvoo factory has manufactured electrical installation products for a long time; the factory’s 110 or so employees and 50 robots annually produce about 25 million units mainly for the Nordic markets. Technical plastics, which are subject to strict quality and production standards, are used in the products.

“ABB is a Nordic frontrunner in the construction sector, and is now showing the way forward in circular economy solutions,” Seppo Kuusela from Fortum’s Recycling & Waste business unit describes the fruits of the cooperation.

ABB aims to reduce its carbon footprint

One of the sustainability targets of ABB’s Installation Products is to reduce the carbon footprint. It was decided to take the first developmental steps in materials; the volumes of plastic electrical installation products are significant on a yearly level, so it would be assumed that this would be impactful.

A variety of alternative solutions were mapped – from bioplastics to recycled plastics – but it quickly became clear that the Fortum Circo® recycled plastic from Finland had precisely the values ABB was looking for: consistent quality, versatility, domestic origin, and responsible recycling. The development work was accelerated by the spring 2020 regulation that construction sites must recycle 70% of materials.

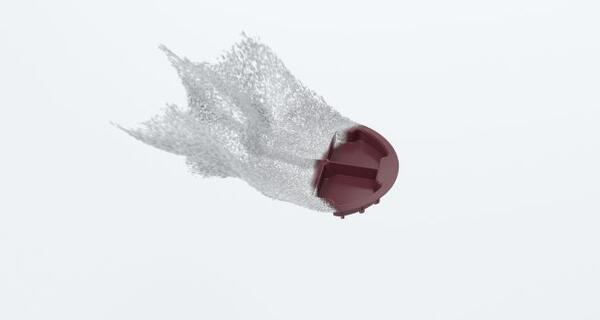

“Fortum Circo® recycled plastic was selected as the material for ABB’s junction box covers because the covers have a relatively short life cycle,” ABB’s Project Manager Marie-Sofie Seger says about the phases of the development work.

The junction box cover is used only during construction; after installation, the cover is removed from the junction box that remains inside the wall.

Recycled plastic as a replacement for virgin plastic

Since January 2020, all ABB junction box covers sold in Finland have been produced from recycled plastic raw material. They are manufactured from recycled plastic granules that are delivered to Porvoo from Fortum’s Riihimäki plastics refinery.

“We are really satisfied with the raw material. We have been able to create a recycled material recovery chain to produce the product with a small carbon footprint in line with circular economy principles,” says Marie-Sofie Seger from ABB.

The product development project advanced agilely in collaboration with Fortum, the raw material fulfilled ABB’s test requirements for technical plastics and its properties were top notch. Prior to taking the recycled plastic into use, ABB also audited Fortum Circo’s production and quality.

The pigment was added to the Fortum Circo® raw material to give it the ABB trademark red colour. “The red colour in the new covers is lighter than before, and the aim is that it communicates the origin of the material, recycled consumer plastic waste. The colour also has an important function because it stands out well against, e.g., the grey cast surface in concrete elements,” Product Manager Petri Kotilainen notes about the end result of the product development.

A circular economy through collaboration

The total carbon footprint of the junction box covers made in Porvoo is estimated to decrease by 21,000 kilos on an annual basis. This is equivalent to the hot water consumption of one average Finn over a period of 77 years.

“The impact at the size-class of ABB is still moderate, but most important is that the first step has been taken successfully, and we can press forward from here,” says Marko Utriainen, SVP, Head of ABB Oy.

The new recycled material has been well received at job sites and by wholesalers, and the feedback has been nothing but positive. ABB believes that creating partnerships is one of the most important issues in a circular economy.

“Fortum is a good partner that shares the same values with us; it knows plastics and also wants to drive advancements forward. The depth of the partnership is tested particularly if there are disruptions in the process. For us it is important that the material cycles through in Finland and we are able to achieve a smaller carbon footprint,” concludes ABB’s Marko Utriainen.

Read more about ABB Group here.